Cost Savings

The purchase and operation of a GN2 nitrogen generator vs purchased liquid or gaseous nitrogen will result in a cost savings of 75% to 92% for nitrogen utilization.

The base price of purchasing nitrogen in a gaseous or liquid form can vary from $2.88 to $0.35 per 100 ft3. The price range will be a result of volume consumption, type of product, location, or vendor. Many of the following additional costs are generally incurred in addition to the base price further elevating total product costs.

Delivery Costs

Monthly Cylinder/Tank Rental Fees

Bulk Evaporative Loss

Handling and Purchasing Labor Costs

Additional Site Liability Insurance

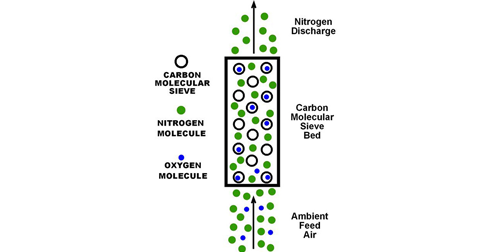

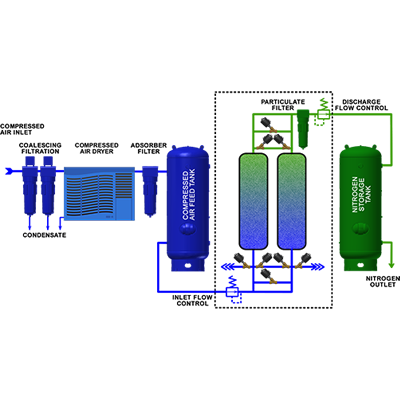

The earth’s atmosphere is comprised of approximately 78% nitrogen and 21% oxygen. A PSA nitrogen generator removes the oxygen portion of the atmospheric makeup through a process called regenerative adsorption. A product called Carbon Molecular Sieve commonly referred to as CMS performs the adsorption portion of the process. Dual towers are the key component of the regenerative part of the process that allows the CMS to adsorb oxygen in one tower while the other tower is regenerating the CMS from previously adsorbed oxygen. When the current tower becomes saturated with oxygen the towers invert and the regenerated tower begins adsorbing oxygen while the other begins regeneration. This cyclic action continues allowing the GN2 to produce a steady stream of nitrogen gas. This process is commonly known as Pressure Swing Adsorption (PSA).

Food and Beverage

Breweries and wineries take great care to prevent oxidation during all processing steps and packaging to enhance product quality. Nitrogen can also provide an inert atmosphere during the mashing and lautering operations. Increasing the nitrogen levels in the finished product to enhance foam characteristics is also common.

Metal Fabrication

Nitrogen is utilized as a purge gas with stainless steel tube welding. It is also used to support plasma and laser cutting systems. By using high purity (99.9% to 99.99%) nitrogen, it is possible to eliminate oxide edges and the need for additional handling labor.

Metal Production

Nitrogen is used to protect metals such as steel, copper and aluminum during annealing, carburizing and sintering operations.

Electronics & Soldering

Nitrogen prevents oxidation while manufacturing semiconductors and printed circuit processes such as wave soldering. It is also used to enhance solvent recovery systems by eliminating the use of chlorofluorocarbons for cleanup.

Modified Atmospheric Packaging

Nitrogen extends shelf-life in packaged foods by preventing spoilage due to oxidation, mold growth, moisture migration and insect infestation.

Controlled Atmosphere Storage

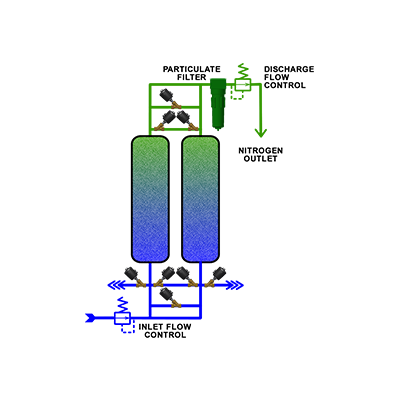

The basic GN2 model includes inlet and discharge flow controls and a primary particulate filter. Proper air preparation and tanks are required for a complete installation.

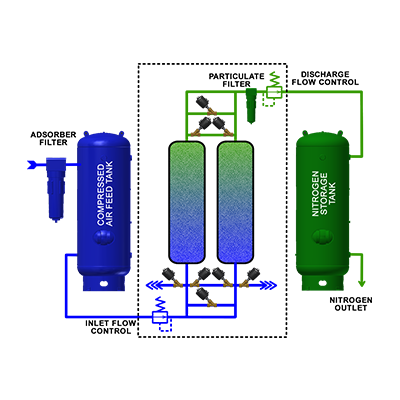

The XP1 package supplies the appropriate feed and nitrogen storage tanks with a protective carbon filter. The package requires a clean dry supply of compressed air.

The GN2 package is designed to provide a turnkey standard pressure nitrogen generation package that only requires the supply of untreated compressed air.

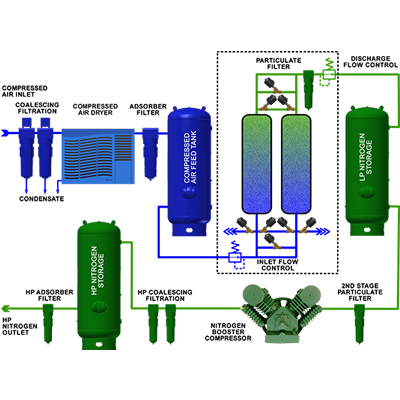

The GN2-XP3 package is designed to provide a turnkey high pressure nitrogen generation package that only requires the supply of untreated compressed air.